Solutions

-

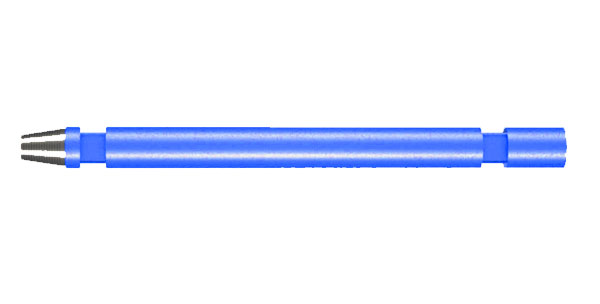

- Drilling Tools T38 3660Mm MM

Drilling Tools T38 3660Mm MM MF Thread...

-

- Hex22 Pneumatic Rock Drilling Tool

Small Hole Drillig Tools Hex22 7/11/12 Degrees Tools Taper Drill Rod...

Drill Pipe

The name “Overburden Drilling” results from the composition of the earthcrust. The bedrock is covered with loose layers of earth consisting of sand,gravel

The name “Overburden Drilling” results from the composition of the earthcrust. The bedrock is covered with loose layers of earth consisting of sand,gravel, boulders combined with loose ground and other deposits. All theseformations are grouped together under the umbrella term “Overburden”,which overlies the bedrock.

Certain drilling processes make it necessary to support the wall with tubes.The system shown here has two rotary units that can rotate opposite to eachother. The rods counter-rotate independently. Air or water is flushed down thecentre of the inner drill string to the end of the drill hole. It discharges theborings in the ring space between both rods through the flushing holes above. The slide of the rotary drives allows the inner rod to move ahead the outerrod and can even be pulled back. The pilot effect of the inner rod gives betteralignment. So, these systems are especially suitable for horizontal drilling, e.g.injection drilling for tunnelling and exploratory drilling.

Depending on the ground conditions, the drilling can be made either withrotary drill bits or DTH-hammers. Another possible way to discharge the borings is to use auger drill rods, especially, if flushing with air or water is notallowed for construction or environmental reasons. As it is not possible withthis system to drill the whole drill string in together, the drilling is madeseparately. First the outer casing, followed by the inner string.

| Model(D) | Wall thickness(h) | Thread(C) | I.D./C1 | Wrench

d |

Flat size

K |

Length/L | Weight | Part No. |

|

76(2) |

6.5 | API 2 3/8REG | 32 | 57 | 45 | 3000 | 40 | M76/6.5-30-01 |

| 8.5 | API 2 3/8REG | 32 | 57 | 45 | 3000 | 48 | M76/8.5-30-01 | |

|

89(3 1/2)

|

6.5 | API 2 3/8REG | 32 | 70 | 165 | 3000 | 48 | M89/6.5-30-01 |

| 8.5 | API 2 3/8REG | 32 | 70 | 45 | 3000 | 58 | M89/8.5-30-01 | |

| 6.5 | NC26 | 40 | 70 | 45 | 3000 | 48 | M89/6.5-30-04 | |

| 8.5 | NC26 | 40 | 70 | 45 | 3000 | 48 | M89/8.5-30-04 | |

| 102(4) | 6.5 | API 3 1/2REG | 45 | 83 | 51 | 3000 | 56 | M102/6.5-30-02 |

| 8.5 | API 3 1/2REG | 45 | 83 | 51 | 3000 | 67 | M102/8.5-30-02 | |

| 6.5 | NC31 | 45 | 83 | 51 | 3000 | 56 | M102/6.5-30-05 | |

| 8.5 | NC31 | 45 | 83 | 51 | 3000 | 67 | M102/8.5-30-05 | |

| 114(4 1/2) | 6.5 | API 3 1/2REGA | 45 | 95 | 51 | 3000 | 63

|

M114/6.5-30-02 |

| 8.5 | API 3 1/2REG | 45 | 95 | 51 | 3000 |

76 |

M114/8.5-30-02 | |

| 6.5 | NC35 | 60 | 95 | 51 | 3000 | 63 | M114/6.5-30-06 | |

| 8.5 | NC35 | 60 | 95 | 51 | 3000 | 76 | M114/8.5-30-06 | |

| 127(5) | 8.5 | API 3 1/2REGA | 45 | 108 | 51 | 3000 | 86 | M127/8.5-30-02 |

| 127(5) | 8.5 | NC38 | 60 | 108 | 51 | 3000 | 86 | M127/8.5-30-07 |

| 133(5 1/4″) | 10 | API 3 1/2REG | 45 | 114 | 51 | 3000 | 102 | M140/9.2-30-02 |

| 140(5 1/2″) | 9.2 | API 3 1/2REG | 45 | 121 | 51 | 3000 | 101 | M140/9.2-30-02 |

| 146(5 3/4″) | 10 | API4 1/2REG | 60 | 127 | 55 | 3000 | 113 | M146/9.2-30-03 |

| 152(6″) | 8.5 | API4 1/2REG | 60 | 133 | 55 | 3000 | 105 | M152/8.5-30-03 |

| 168(6 5/8″) | 10 | NC50 | 60 | 149 | 55 | 3000 | 132 | M168/10-30-08 |

| 178(7″) | 10 | API4 1/2REG | 60 | 159 | 55 | 3000 | 140 | M178/10-30-03 |

Inquiry

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry